Regulation of Dangerous Goods

Main ContentChapter 4.2 Filling Ratio Requirements

| 4.2.1 |

Legal Requirements |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.1.1 | Pursuant to Paragraph 5 of Schedule 6 of Cap. 295G:

S2DG packing must be filled in conformity with the filling ratio specified in the code of practice, if applicable. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.2 | General Application | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.2.1 | This chapter specifies filling requirements of Class 2 DG which is stored in pressure receptacle in the form of compressed gas, liquefied gas or dissolved gas. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.2.2 | Manufacture licence for Class 2 DG shall be obtained for the purpose of filling of pressure receptacle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.2.3 | Prior to filling, the person who fills the pressure receptacle shall perform an inspection of the pressure receptacle and ensure that the pressure receptacle shall only be filled with the gas or gas mixture as specified in the approval of pressure receptacle given by FSD. Shut-off valves shall be closed after filling and remain closed during storage and conveyance. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3 | Filling Requirements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

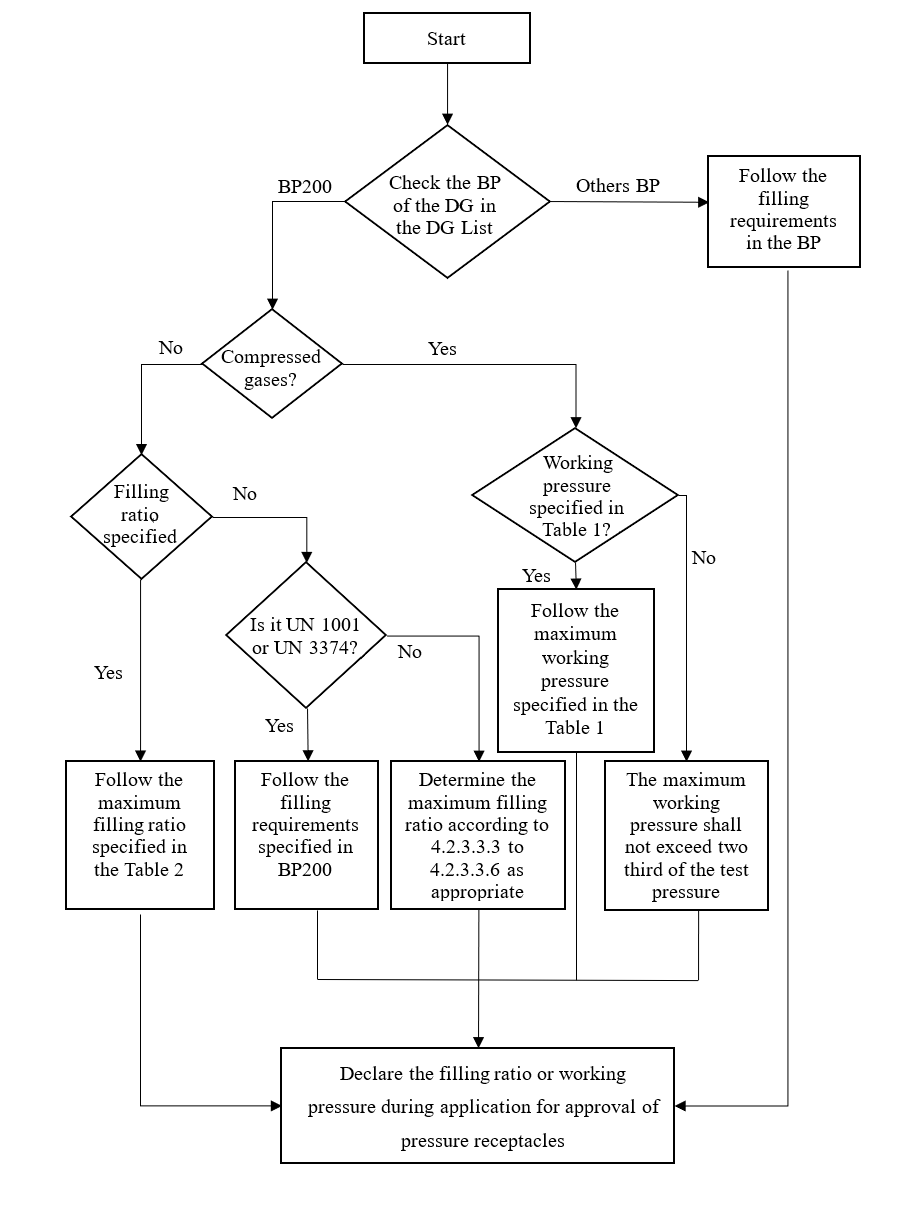

| 4.2.3.1 | Pressure receptacle shall be filled according to the filling requirements and provisions specified in the appropriate BP provided at column 7 of the DG List for the specific DG being filled. Details of the BP are provided at Appendix 5 of the Code. Reactive gases and gas mixtures shall be filled to a pressure such that if complete decomposition of the gas occurs, the working pressure of the pressure receptacle shall not be exceeded. Bundles of pressure receptacles shall not be filled in excess of the lowest working pressure of any given pressure receptacle in the bundle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.2 | It is reminded hat 5the filling ratio, working pressure and test pressure, if applicable, shall be declared during the application for approval of pressure receptacle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3 | Filling Ratio of Pressure Receptacle for Liquefied Gases and Dissolved Gases | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3.1 | The specific maximum filling ratio and minimum test pressure for different DG shall comply with the details as stipulated in the corresponding BP of the DG with details at Appendix 5. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3.2 | For high pressure liquefied gases, the minimum test pressures and maximum filling ratios other than those specified in the BP of the DG at Appendix 5 can be used, provided that

(a) for UN 2192 GERMANE and UN 2676 STIBINE, the filling ratio of the gas is limited which the pressure does not exceed two thirds of the test pressure of the pressure receptacle when complete decomposition occurs; or (b) for other cases, the maximum filling ratio shall be such that the settled pressure at 65°C does not exceed the test pressure of the pressure receptacle. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

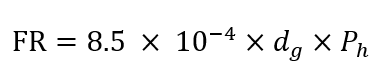

| 4.2.3.3.3 |

For high pressure liquefied gases and gas mixtures for which relevant data are not available, the maximum filling ratio shall be determined as follows: where FR = maximum filling ratio dg = gas density (at 15°C, 1 bar) (in g/L) Ph = minimum test pressure (in bar)

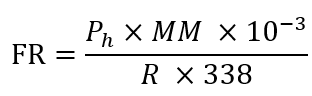

If the density of the gas is unknown, the maximum filling ratio shall be determined as follows: where FR = maximum filling ratio Ph = minimum test pressure (in bar) MM = molecular mass (in g/mol) R = 8.31451 × 10-2 bar·L/mol·K (gas constant) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3.4 | For low pressure liquefied gases, the maximum mass of contents per litre of water capacity (filling factor) shall equal 0.95 times the density of the liquid phase at 50°C; in addition, the liquid phase shall not completely fill the pressure receptacle at any temperature up to 60°C. The test pressure of the pressure receptacle shall be at least equal to the vapour pressure (absolute) of the liquid at 65°C, minus 100 kPa (1 bar). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

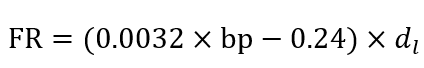

| 4.2.3.3.5 | For low pressure liquefied gases and gas mixtures for which relevant data are not available, the maximum filling ratio shall be determined as follows:

where FR = maximum filling ratio bp = boiling point (in kelvin) dl = density of the liquid at boiling point (in kg/L) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3.6 | For liquefied gases charged with compressed gases, both components – the liquefied gas and the compressed gas – have to be taken into consideration in the calculation of the internal pressure in the pressure receptacle. The maximum mass of contents per litre of water capacity shall not exceed 0.95 times the density of the liquid phase at 50°C; in addition, the liquid phase shall not completely fill the pressure receptacle at any temperature up to 60°C. When filled, the internal pressure at 65°C shall not exceed the test pressure of the pressure receptacle. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.3.7 | During transitional period, pressure receptacle can also be filled to the maximum filling ratio as specified in the following table from Cap. 295B:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.4 | Filling Ratio of Pressure Receptacle for Compressed Gases | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.4.1 | The maximum filling ratio, i.e. maximum working pressure, for compressed gases stored in pressure receptacle shall not exceed maximum filling ratio specified in Table 1 of BP 200 at Appendix 5 or two thirds of the test pressure if no filling ratio is specified. In no case shall the internal pressure at 65°C exceed the test pressure. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.2.3.5 |

Flowchart for Determining the Filling Requirements |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||